Machine Tools

Made in the USA

Cutting edge design in 3,4 & 5 axis configurations, based on proven robust machines. Bertsche Machine Tools can be customized to meet your application needs.

Size matters

Innovative portal machine designs reduce the overall machine tool footprint and increase productivity by a factor of two.

Micron Cleaning & Deburring

100% pristine cleanliness

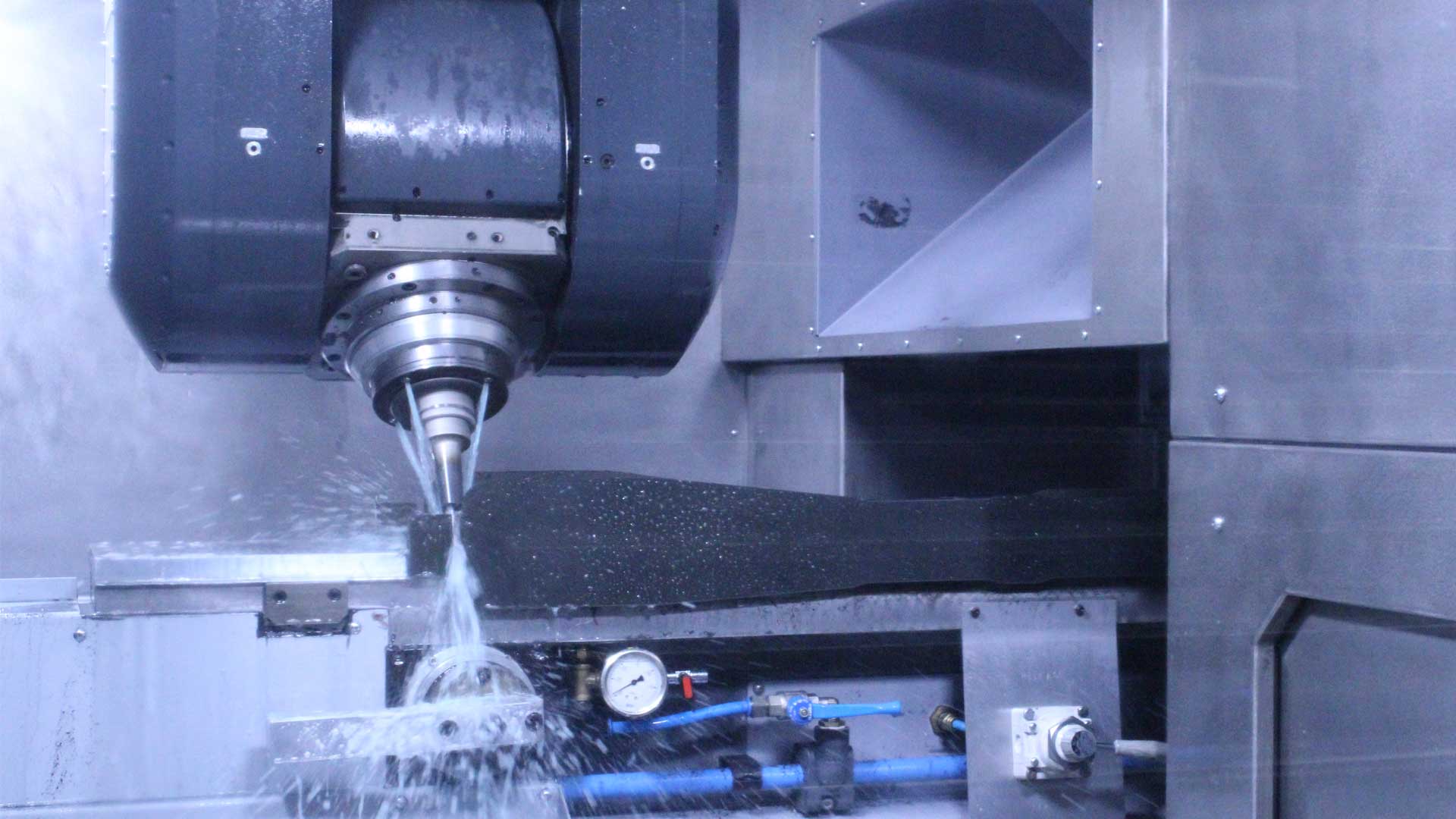

Only high pressure water cleaning & deburring is capable of meeting the evermore stringent clean requirements demanded by manufacturers.

The flexibility of CNC

The Bertsche iJET series of machines combine the intelligence of CNC and the power of high pressure water to precisely direct high pressure water jet to critical areas to clean and deburr part.

Technology Overview

Standard and custom 3, 4 and 5 axis CNC machine tools, high pressure water cleaning machines and automatic tool storage and retrieval systems.

Standard and custom 3, 4 and 5 axis CNC machine tools, high pressure water cleaning machines and automatic tool storage and retrieval systems.

Experience Matters

Bertsche Engineering Corporation, established in 1972, is a

designer and builder of high performance standard and custom machine tools, automatic tool changers, robotics and high

pressure washing systems. Major industrial sectors represented among Bertsche Engineering customers are aircraft and aerospace industries, mold and die, fluid product and automotive industries. Our customers are diverse and range in size from small machine shops to Fortune 100 Manufacturers.

Since 1992, Bertsche Engineering has pioneered the development of very high feedrate long bed traveling column-machining centers. Available as vertical spindle, as horizontal spindle, and as 5-Axis machines, they feature very long travels in X, very high spindle RPM, feed and rapid rates and high acceleration–all necessary components for high feedrate machining. Our products are designed and manufactured in the U.S.A.

Years Established

INSTALLATIONS

Latest News

Dual Spindle – One Large Working Envelope.

Manufacturers can ramp up product. There will be more than one new machine introduced at IMTS 2006 that will be billed as a China beater, or as an India and rest-of-Asia beater, for that matter. U.S. manufacturers ranging from entrepreneurial job shops to Tier...

High Speed 5 Axis Bridge Machine with Smart Fixturing System

Bertsche Engineering introduces new High Speed 5 Axis Bridge Machine with Smart Fixturing System to manufacture complete Floor Systems for the 787 Boeing Dreamliner. Featuring a direct drive 2 axis rotary head this 5 axis machine manufactures complete in a single...

Reduce product failure by implementing an eco friendly high pressure waterjet cleaning and deburring process.

The Bertsche iJet provides multi-station high pressure water deburr and cleaning system with integral part handling that completely washes, removes chip burrs, rinses cleans and dries six faces of a part. iJet is designed for manufacturers of complex mid to high...