iJET 200

Robotic high pressure waterjet cleaning & deburring

Compact footprint full featured design

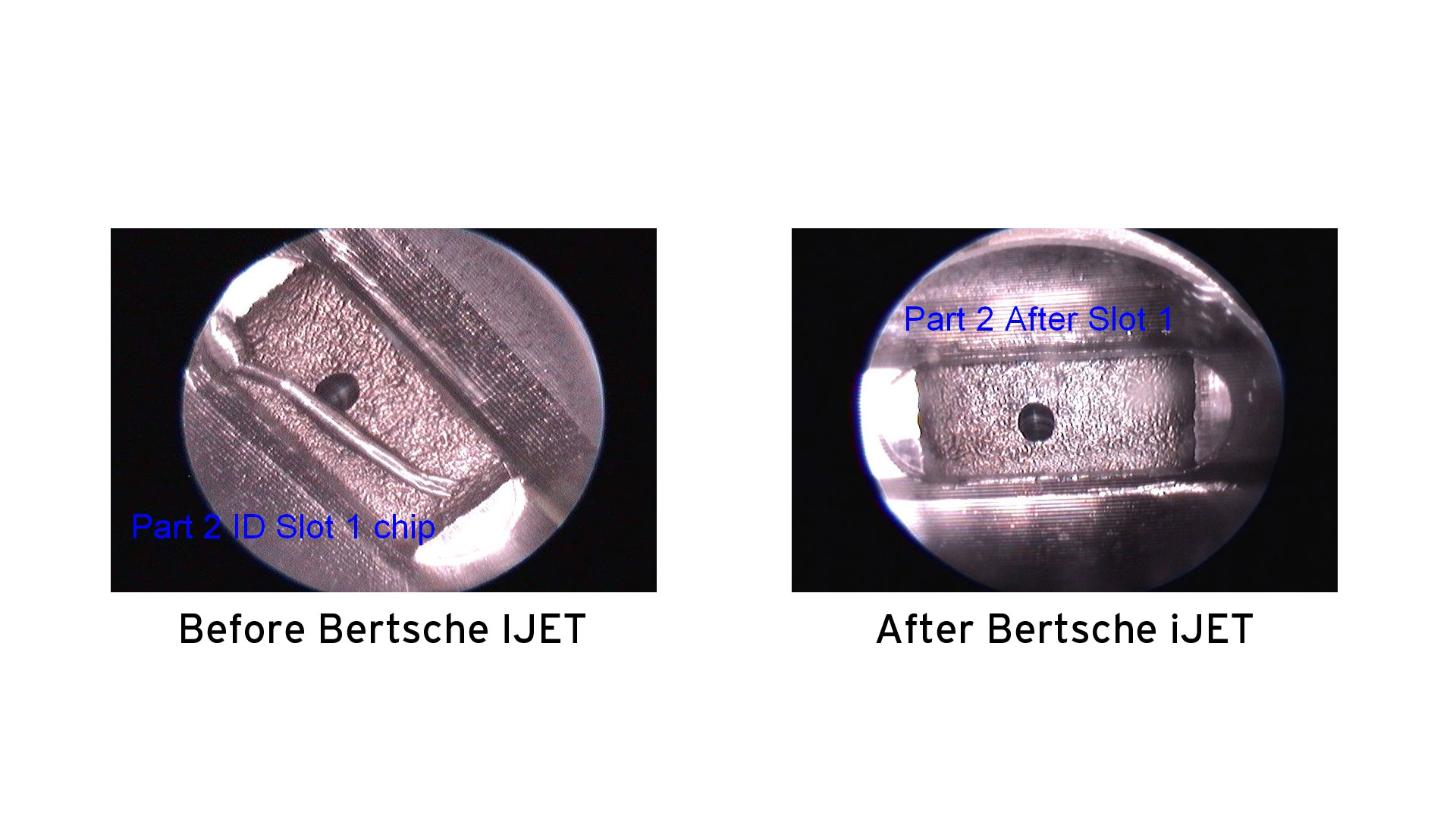

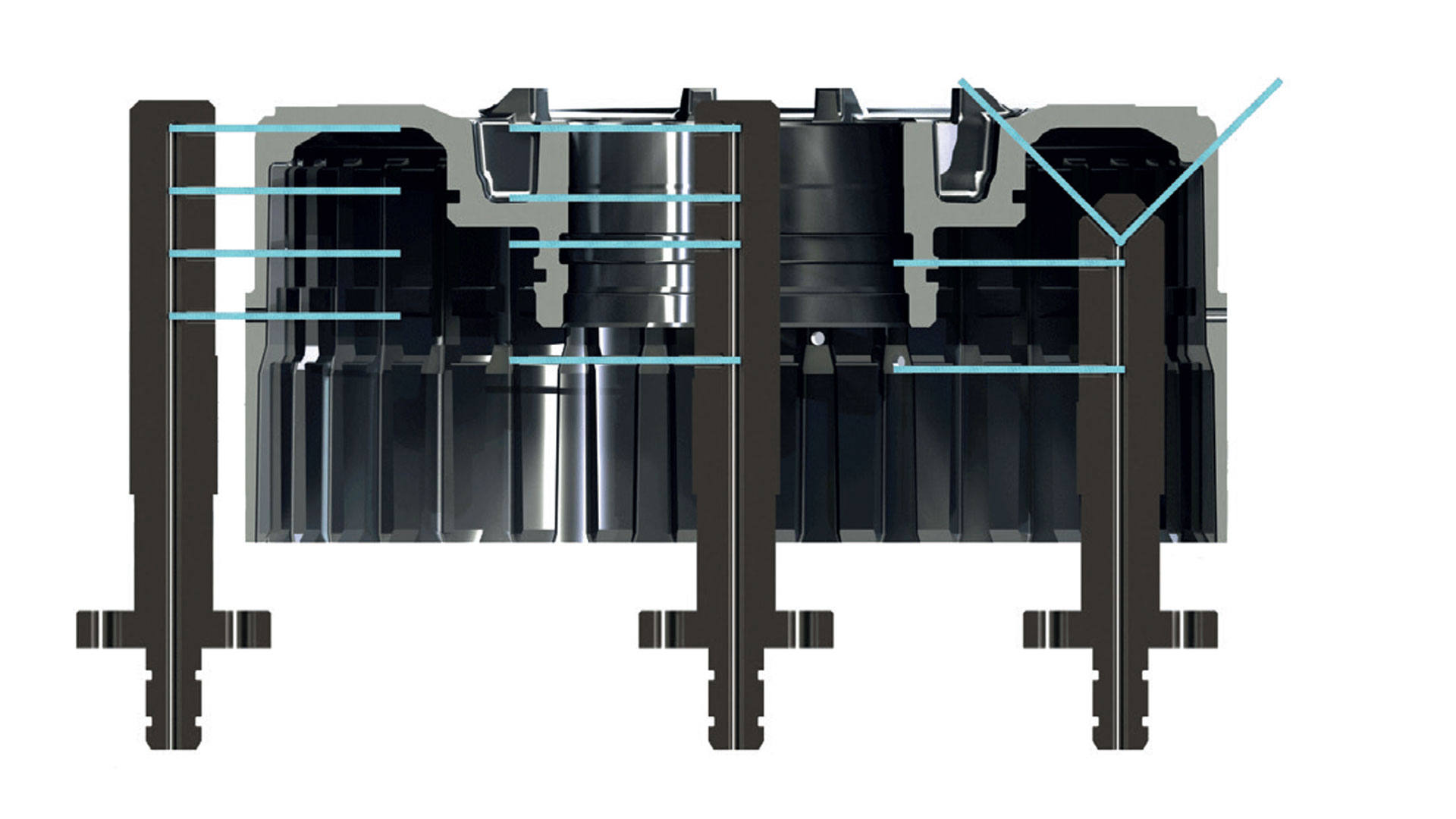

The iJET 200 consists of a multi axis robot that moves parts over a series of single point horizontal and vertical rotary nozzle stations for single feature chip burr removal and manifold stations for multiple feature cleaning. The operating principle relies on a high pressure (up to 20,000psi) intensified and directed water jet to blast chips from hard to access locations inside the part as well as externally.

Parts are moved over one or more direct jets or multi-orifice rotary horizontal and vertical nozzles. The heavy duty robot is designed to also mechanically deburr parts using such tools as rotary files, wire brushes and similar tooling on surfaces that can not be fully cleaned with water. For higher volume applications special multi-feature station manifolds remove chips, clean multiple features on one or more faces. The standard machine configuration can accept a combination of up to six single and or multi feature wash stations. The machine has a small footprint and can easily be integrated to external (to the machine) part conveying systems.