Machine Tools

Made in the USA

Cutting edge design in 3,4 & 5 axis configurations, based on proven robust machines. Bertsche Machine Tools can be customized to meet your application needs.

Size matters

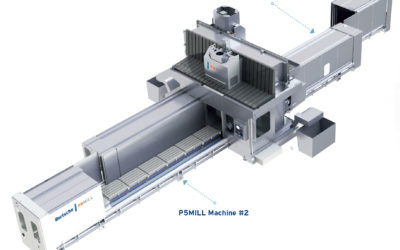

Innovative portal machine designs reduce the overall machine tool footprint and increase productivity by a factor of two.

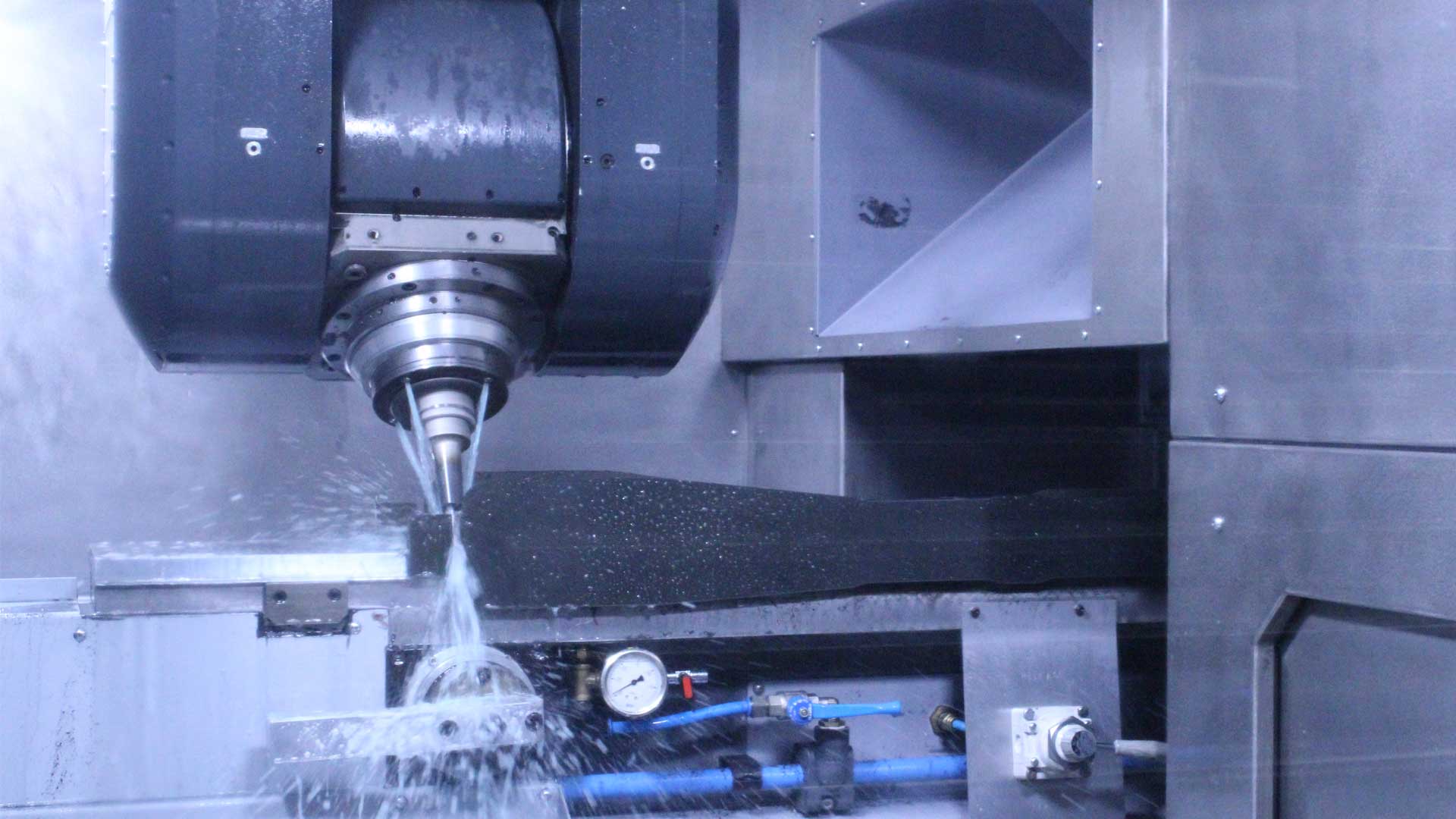

Micron Cleaning & Deburring

100% pristine cleanliness

Only high pressure water cleaning & deburring is capable of meeting the evermore stringent clean requirements demanded by manufacturers.

The flexibility of CNC

The Bertsche iJET series of machines combine the intelligence of CNC and the power of high pressure water to precisely direct high pressure water jet to critical areas to clean and deburr part.

Technology Overview

Standard and custom 3, 4 and 5 axis CNC machine tools, high pressure water cleaning machines and automatic tool storage and retrieval systems.

Standard and custom 3, 4 and 5 axis CNC machine tools, high pressure water cleaning machines and automatic tool storage and retrieval systems.

Experience Matters

Bertsche Engineering Corporation, established in 1972, is a

designer and builder of high performance standard and custom machine tools, automatic tool changers, robotics and high

pressure washing systems. Major industrial sectors represented among Bertsche Engineering customers are aircraft and aerospace industries, mold and die, fluid product and automotive industries. Our customers are diverse and range in size from small machine shops to Fortune 100 Manufacturers.

Since 1992, Bertsche Engineering has pioneered the development of very high feedrate long bed traveling column-machining centers. Available as vertical spindle, as horizontal spindle, and as 5-Axis machines, they feature very long travels in X, very high spindle RPM, feed and rapid rates and high acceleration–all necessary components for high feedrate machining. Our products are designed and manufactured in the U.S.A.

Years Established

INSTALLATIONS

Latest News

When Machining Long Parts, Machine Shop Climate Matters

Machining long titanium tufting needle bars required a milling machine with a super-long X-axis travel. But the real challenge was thermal compensation in the Georgia heat. It gets hot in Dalton, Georgia, where Tuftco Corp. manufactures carpet tufting machines. These...

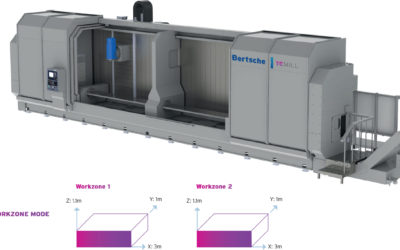

The Dual 5 Axis TCMILL MACHINING CENTER

The TCMILL Series comes packed with flexibility and can be configured for different work modes depending on your application. The TCMILL is a powerful 5 Axis high performance travelling column machining center with standard travels of 236″/275″/315″/470″ inches in X...

The 2 in 1 P5x5 By Bertsche

With significant new business and rising monthly production rates this customer required the additional capacity of two machines but was constrained by a building that could only fit one. Faced with a critical decision, build a new building and house two new machines,...