The TCMILL Series comes packed with flexibility and can be configured for different work modes depending on your application. The TCMILL is a powerful 5 Axis high performance travelling column machining center with standard travels of 236″/275″/315″/470″ inches in X and 40″ inches in Y. With its high dynamics, feed and rapid rates of 100m/min provide the performance for high metal removal rates in aluminum monolithic parts and the dynamic agility for thick wall composite drilling, routing, & milling. The “high feed force” is ideal for heavy steel or titanium machining with up to 5,200 lbs, high torque spindle and rigid machine structure. Designed and built in the USA, the TCMILL series is American tough.

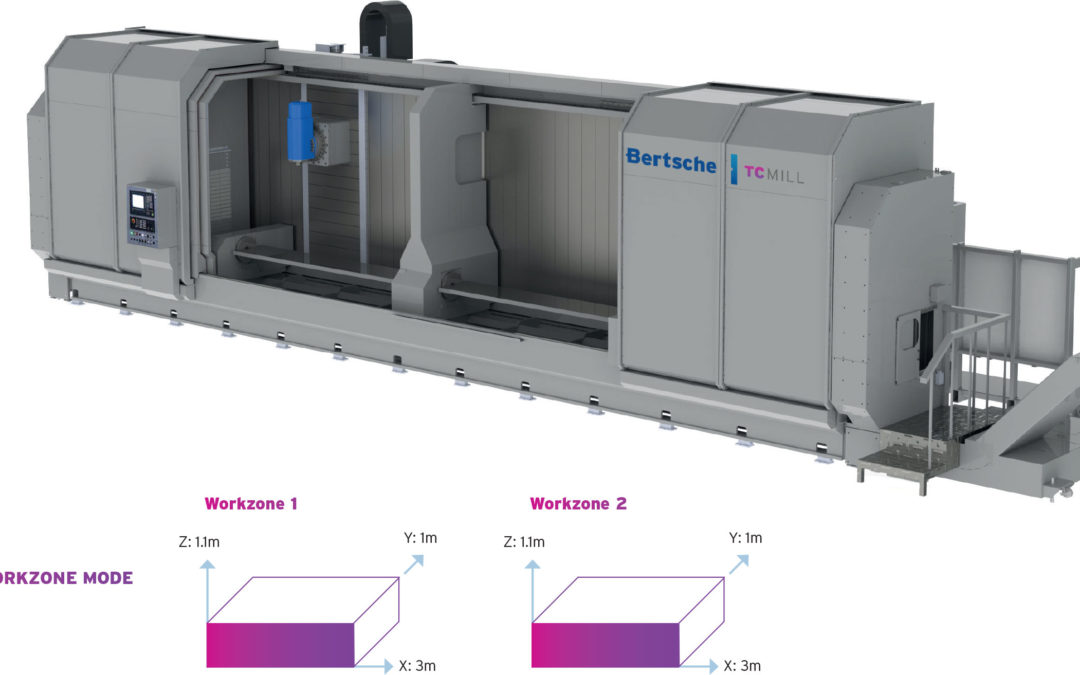

DUAL WORKZONE MODE

> 3m between NC rotary tables.

> Dual synchronized NC Rotary Tables work in tandem

> 60 tools total, 2×30 tool direct exchange tool changer – 1 per work zone

SINGLE WORKZONE MODE

> When large part machining is required the

work zone divider can be removed, enabling 5

axis machining of long parts >6 meters.